When SCADA is the Right Solution

What is a SCADA System?

SCADA systems are being used practically all over the world for supervisory control and data acquisition. Understanding a useful SCADA and how to make it starts with an understanding about the role of a SCADA in a system.

The need for the SCADA evolved through time after agrarian and handicraft economies shifted rapidly to industrial and machine-manufacturing economies during industrial revolution in the 18th century. First, they made machines to do the repeatable processes faster, with more consistency and with greater precision than people. A lot of it was about eliminating human error. While this first step in the industrial revolution was to replace people with machines for the work that was previously done by hand and to minimize human interaction with the process, it opened up the question about whether it was possible to completely eliminate the human factor throughout the whole process. By saying the whole process, I mean the actual work that was previously done with bare hands and the management work – the work of connecting different parts of manufacture to complete the process.

For example, there was a time when mechanized processes were made of multiple machines operated by people including at least one person who would be the supervisor of the whole process. The process supervisor was there to make sure the process continuously does what it is meant to do and to make that happen, machine operators reported to this person in case a problem arose that could potentially stop the process. Since the supervisor had an overview of the process, he could make the most appropriate decisions to keep the process running.

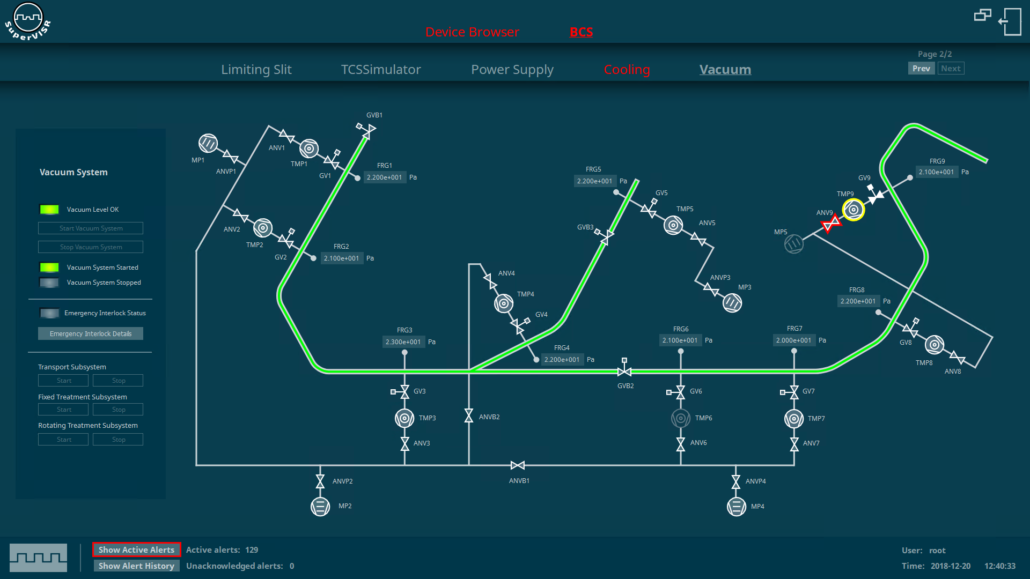

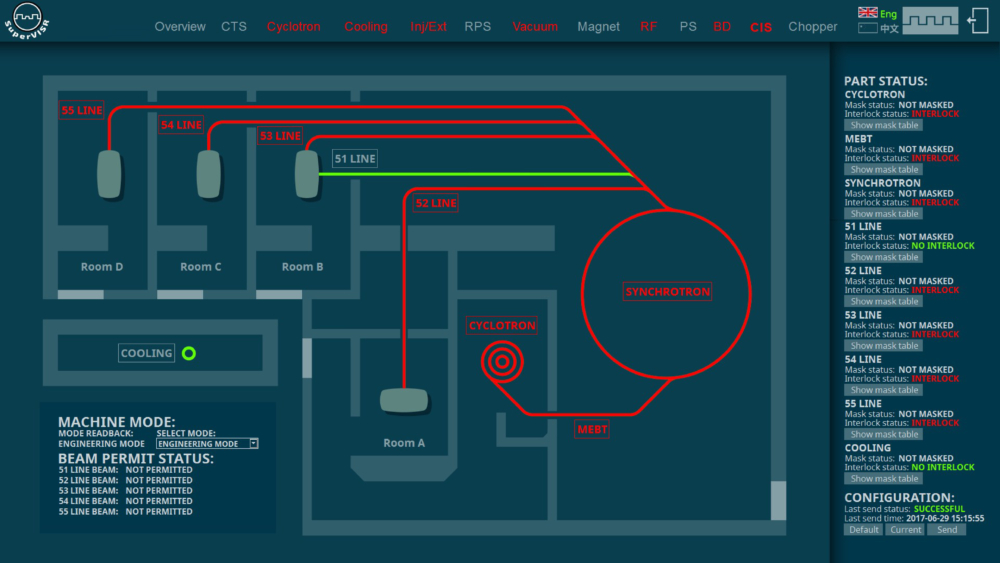

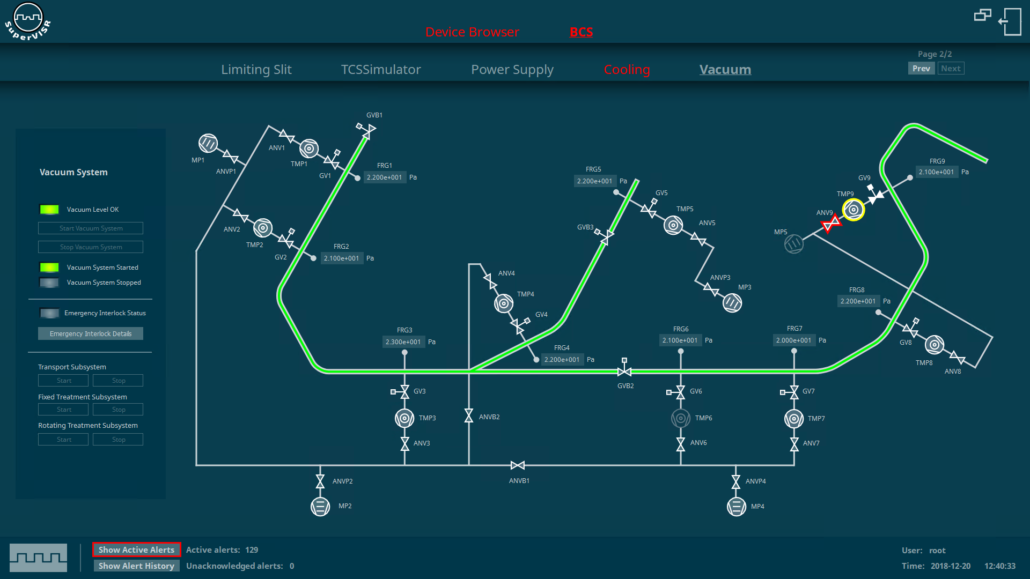

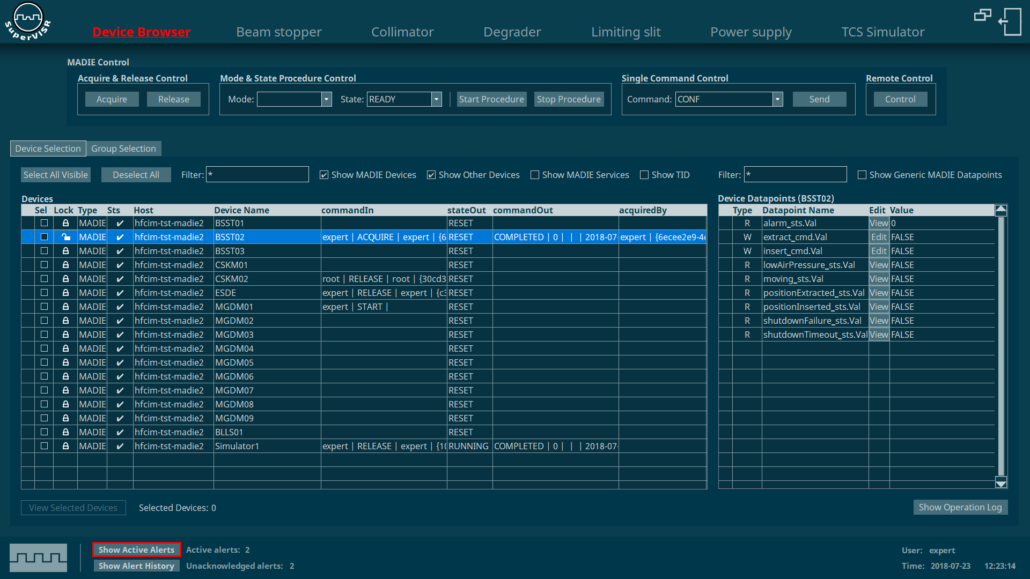

And this is the purpose of the SCADA. It centralizes control, congregates and exposes data towards other system components on higher levels and attempts to minimize human interaction with the process control.

Determining if the Right SCADA Solution

Only after we’ve decided whether SCADA is a solution to our problem can we start asking ourselves what we want the SCADA to do through the following set of questions:

1. What does the system require to be supervised and acted upon (by the SCADA), to ensure the process will do what we want it to do?

- What are the building blocks of the process that need supervision and what exactly does the supervision mean for every single building block?

- What are the supervision tasks that are common for all the building blocks of the process?

2. What are the possible events in the system that would negatively impact on what we want the system to do (machine failure, software bugs, human errors) and which of those need be handled by SCADA?

- How can these be events handled to avoid negative impacts on the system?

- Is it possible to detect these events?

- How will the SCADA receive notifications about these events?

- Are there any preventive actions we can take to prevent these events from happening?

3. What supervisory information is required to enable improvements to the system?

- Here is where different kind of SCADA statistics come in including data mining and KPIs.

4. Which parts of the work defined with the first three questions can be automated; which parts do we want to automate and which parts require human intervention/supervision?

- In the case of a fully automated process, you would need a graphical user interface (GUI) with a single start button.

In Conclusion

The key to getting a useful SCADA starts with a conversation with the customer about what they need and a clear conceptual design, guided by the above questions. Only after this process has completed, does it makes sense to choose a specific SCADA technology, e.g. WinCC OA, EPICS, or TANGO) that best fits the job, but that is a topic for another article.