How QualySense Accelerated the Development of Their Machine

Since it was established in 2010 QualySense has pioneered high-speed single kernel technologies and developed high-end solutions for safer and more sustainable value chains covering several agricultural commodities. Recent efforts have focused on developing industrial scale, high-volume sorting equipment.

Key Challenge

Scaling the QualySense QSorter Explorer to an industrial-grade

machine

QSorter Explorer®, the small volume single-kernel sorting robot from which the new generation machine was derived

Their proprietary technology is the successful outcome of a long collaboration between QualySense and leading academic institutions such as the United States Department of Agriculture (USDA), the Swiss Breeding Research Institute (AGROSCOPE), and EMPA, the Swiss Research Institute for Material Research.

QualySense initially made substantial investments in state-of-the-art software and electronics to build the QSorter Explorer, the life science single kernel robot for high-speed accurate analysis and sorting of grains, seeds, and beans.

Cosylab was selected as the optimal software architecture and engineering partner for the high-volume platform development and has worked with the QualySense team since 2017.

The need for a flexible, responsive partner

To be able to continue focusing on their core value proposition which is Life Science algorithm development, QualySense decided to engage a partner that not only has a technical expertise but is also very flexible and can quickly adapt to changes that are constant in the high-tech industry especially in conditions of accelerated product development.

“QSorter Explorer started as a prototyping platform, based on LabView, which was the main idea in our exploration phase. When we wanted to scale the system to the requirements of an industrial-grade machine, it was crucial to redesign the architecture, introduce proper development cycles and make it easier to maintain the system.”

Solution: engineering partnership

Engineering partnership with Cosylab

When the company needed to scale their platform to the requirements of an industrial-grade high-volume machine, Cosylab was selected as their engineering partner for the embedded software framework and system architecture.

“We decided to work with Cosylab because they were flexible, very responsive and able to help us solve our challenges outside our core competences without a lot of up-front investment from our side,”

Cosylab provided the expertise to help define requirements and build an advanced real-time control system for an efficient and robust execution environment for their algorithms to enable unmatched sorting precision for grains, seeds, beans, and other commodities.

Thanks to synergies between both companies, QualySense was able to significantly reduce the lead time for the prototype and set the bases for an increase in effectiveness of their analytical sorting platform.

Advanced Real-Time Control System

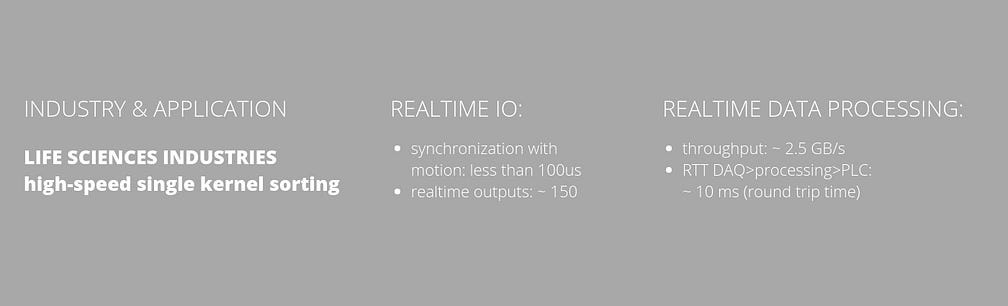

The solution Cosylab has proposed, built and integrated together with QualySense specialists consists of both the control for the machine as well as a high performance and high throughput industrial grade data processing system that includes machine vision and a platform for use case specific classification algorithms.

Cosylab proposed QualySense a two-part solution that decouples industrial hard real-time logic from the data processing, whereas both parts communicate in soft real-time via an Ethernet-based ADS interface.

- The industrial logic that interfaces the actual underlying sorting hardware needed to be robust, real-time, safe and interoperable with other industrial systems. They selected Beckhoff TwinCAT3 based solutions as it had the best fit with requirements and was the simplest solution that allowed to achieve microsecond level timing accuracy.

- The data processing and data acquisition part of the system has been implemented on a high-performance industrial PC running a Windows operating system. Here Cosylab has developed an extensible framework that implements data acquisition and multithreaded execution environment that is responsible for running custom algorithms, in soft real-time, developed by QualySense.

Efficient collaboration

Most of the time, Cosylab team has worked remotely, and joined QualySense on-site for the final testing on their hardware. Teams had regular meetings for important discussions related to architecture design, progress reviews, and handover operations.

“We believe that both sides contributed a lot, especially when there were open points that needed clarifications or further brainstorming. At the end of our collaboration we were able to take control of the software developed by Cosylab and fine tune it to fit perfectly to our industrial needs, keeping the expertise and control for future expansion of the platform under our direct supervision.”

Major gains

The results speak for themselves. Due to the efficient cooperation from both sides, we managed to clearly define the requirements of the machine and optimally select technologies that resulted an advanced real-time control system solution. QualySense was able to significantly reduce the lead time for the high-capacity prototype.

Download the full Case Study on how QualySense accelerated the development of their machine by partnering with Cosylab.