From GIRAFFE to starQ: Engineering the Bridge Between Research and Industry

Quantum technologies have advanced rapidly, but most breakthroughs still live inside carefully tuned lab experiments. These setups are powerful for discovery, yet fragile by design: every system depends on bespoke scripts, lab instruments tied together with USB cables, and researchers who know precisely which knob to adjust when something drifts off course.

This approach is ideal for exploration but insufficient when teams must deliver reliable prototypes, meet funding milestones, or prepare for industrialisation. At that point, the limiting factor is no longer physics, it is engineering.

Why Quantum Needs Engineering-as-a-service

When “it runs on my laptop” stops being good enough, quantum teams need engineering practices that ensure reproducibility and scalability.

Research setups often include multiple waveform generators, microwave sources, DAQ cards, and synchronisation hardware, each with its own latencies, noise sources, and drift. These systems enable innovation, but they cannot form the backbone of a product.

This is where Engineering as a service offers creates value, as a structured approach to bridge the gap. It employs process-driven methodologies, such as requirements capture, system design, interface definitions, timing architecture, validation, and documentation, that enable research concepts to evolve into robust, auditable systems.

What is Engineering as a Service?

Engineering as a service is the professional application of end-to-end engineering, delivered flexibly as part of a customer’s team. For quantum startups and research labs, this means having engineers who understand not only hardware and firmware, but the specific failure modes and bottlenecks of quantum systems.

It directly addresses the most common pain points:

- Turning prototypes into systems that work reliably, not only under ideal lab conditions.

- Struggling with the integration of off-the-shelf instruments or consultant-built components that fail to form a cohesive system.

- Limited internal engineering bandwidth makes it challenging to advance science while meeting investor or grant deadlines.

- Concerns about IP lock-in, where proprietary hardware or vendor-specific ecosystems restrict control and transparency.

Instead of delivering isolated components, engineering as a service focuses on full-system integration, traceable validation, and long-term support, enabling teams to scale confidently.

Quantum Lab to Market: Why It Matters

As quantum technologies mature, expectations from investors, partners, and grant agencies increase.

Demonstrators must be delivered quickly and perform reliably. Building everything in-house is expensive and time-consuming; hiring engineering teams takes time, and consultants often deliver fragmented solutions rather than cohesive systems.

Meanwhile, deadlines do not wait for perfect engineering. Structured engineering reduces integration risk, ensures IP remains with the customer, and allows teams to move forward without wasting momentum.

Practices like defined interfaces, version control, timing architecture, risk assessment, and comprehensive testing aren’t bureaucracy, they are the foundations of systems that can be reproduced, certified, and manufactured.

GIRAFFE: Embedded, High-Fidelity Platform for NV sensing

The philosophy found a practical proving ground in the GIRAFFE project, a European consortium led by Silicon Austria Labs (SAL). The scientific foundation was solid: NV centres offer exceptional sensitivity to rotation when properly controlled.

The engineering challenge was integration: how to achieve high-fidelity nuclear spin readout, implement advanced quantum control algorithms, and perform real-time signal processing without relying on an external computer in a form factor suitable for embedded deployment.

The GIRAFFE project set out in a pioneering effort to build a compact quantum gyroscope based on nitrogen-vacancy (NV) centres in diamond, which has a far higher stability and accuracy than a conventional MEMS gyro.

Engineering the Control Backbone

In GIRAFFE, Cosylab applied structured engineering to take a complex NV-centre quantum gyroscope out of the lab and into an embedded, field-ready control system.

It demonstrated how rigorous engineering, paired with scientific insight, can transform a fragile research setup into a scalable technology. The solution centres on AMD RFSoC technology, which integrates RF data converters and FPGA fabric on a single chip. This architecture supports:

- Deterministic timing and synchronisation across microwave generation, optical control, and readout channels, meeting sub-10 ns requirements for spin manipulation sequences

- High-rate data acquisition and real-time processing directly in programmable logic, eliminating bottlenecks and latency associated with off-chip transfers

- Embedded quantum control algorithms running autonomously on the SoC, enabling closed-loop operation without external CPU dependency

- Modular, scalable design with clean interfaces, allowing SAL to iterate the physics layer independently of the control stack

The result was a fully embedded control unit: quantum control, signal generation, acquisition, and processing integrated into a single platform.

“RFSoC electronics, developed by our partner Cosylab, enabled SAL to perform high-fidelity nuclear spin readout with advanced quantum control algorithms and on-board signal processing in a fully embedded way, without the need for an additional computer.”

Science and Engineering Join in Quantum System Integration

GIRAFFE validated a core hypothesis: that industrial-grade control engineering, applied rigorously to quantum sensing, can deliver performance and integration previously achievable only in bespoke research setups.

Cosylab applied process-driven methodologies, requirements capture, interface specification, version control, validation plans, and traceability to ensure the system could be reproduced, certified, and maintained without relying on tacit knowledge.

Despite its compact form factor, the GIRAFFE control unit delivered:

- Fully embedded operation with no PC tethering

- Real-time quantum feedback loops

- High-fidelity spin readout demonstrated in experimental setups

- Robust multi-channel RF generation and data acquisition

- A modular firmware architecture suitable for future extensions

From an engineering standpoint, GIRAFFE was more than a successful project; it was a validation of its core philosophy, namely that complex quantum systems can be engineered with the same rigour as medical devices or fusion control systems, and that battery-powered quantum sensors for aerospace, defence and navigation are now a reality.

This project was funded within the framework of Quantum Austria by the Austrian “Nationalstiftung für Forschung, Technologie und Entwicklung” (National Foundation for Research, Technology and Development), the FFG and FWF, with support of the Federal Ministry for Science and Research (BMBWF)

From Lab to Fab: Quantum Sensing & NV Control Webinar

February 4, 2026 | Join the "From Lab to Fab" webinar series on quantum sensing, and learn about exciting breakthroughs in quantum sensing applications using NV centers.

From GIRAFFE to starQ: Accelerating Industrialisation

The lessons learned in GIRAFFE did not end with the demonstrator; they continued to be applied and directly shaped the development of starQ, Cosylab’s more versatile, industrial-grade platform.

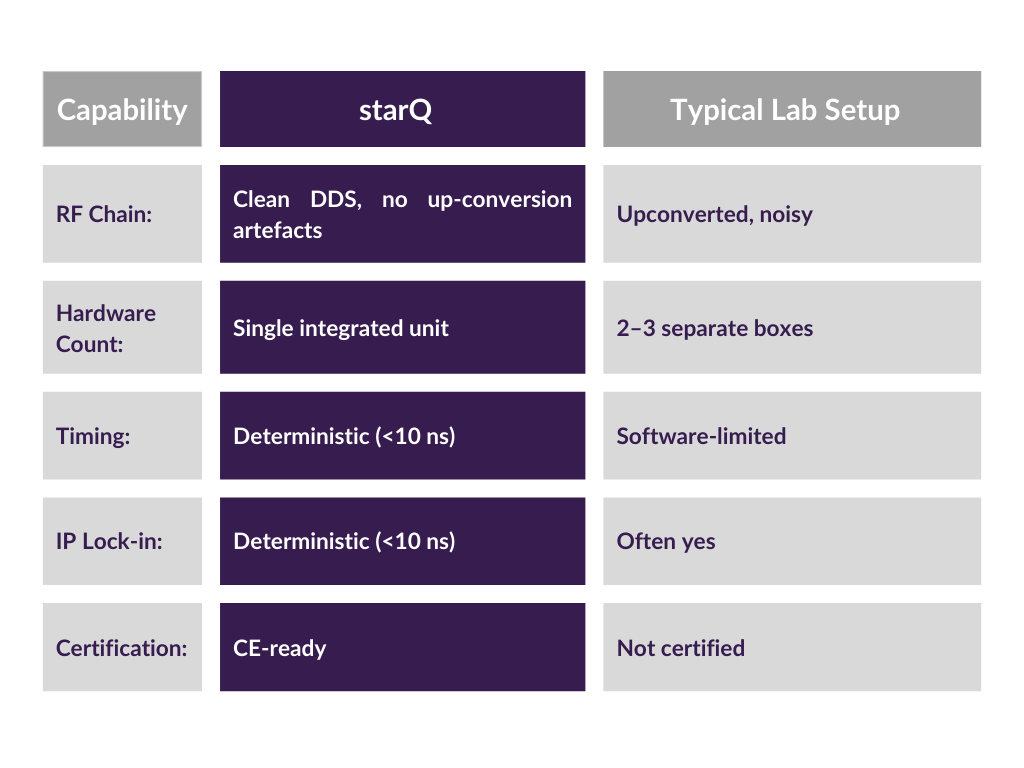

Everything proven in GIRAFFE, such as embedded operation, deterministic timing, IP safety, scalable firmware, and certifiable design, became the foundation for starQ. starQ is a pre-integrated, flexible, and scalable system designed to traverse the gap between research prototypes and commercial demonstrators.

Foundation for starQ: Transitioning from Lab to Demonstrator

starQ retains GIRAFFE’s RFSoC-based foundation, high-bandwidth, low-noise signal generation with deterministic timing, and adds layers of abstraction, documentation, and support for integration into varied setups.

This means that starQ, in contrast with GIRAFFE, which was a custom demonstrator for a specific NV-centre gyroscope, serves as an industrial-grade control product with standardised interfaces, CE-ready documentation, and an architecture designed for manufacturing, not just prototyping, a wide range of quantum devices.

starQ’s is built with three core design principles

- Pre-integrated and tested: timing, signal generation, data acquisition, and processing subsystems are engineered and validated together, reducing integration risk and setup time from weeks to days.

- CE-pending: hardware and firmware design follows traceable, QA-backed processes aligned with certification requirements, so the path from demonstrator to certifiable product is clear from day one.

- IP boundaries by design: the platform is decoupled from customer-specific quantum physics and application algorithms. starQ provides the reliable control infrastructure beneath it, no lock-in, transparent documentation, and interfaces you can build on or replace.

Enabling the Lab-to-Market Transition

Quantum startups and research labs face a recurring tension: milestones demand working demonstrators, but resources are constrained. Building a custom control stack diverts engineering effort from the quantum innovation itself.

Relying on fragmented vendor solutions introduces integration risk and limits flexibility. starQ offers a third path: start with a stable, modular platform, customise where differentiation matters, and move from prototype to demo faster with lower technical risk.

For teams working on NV gyroscopes, magnetometers, or other diamond-based sensing systems, starQ can serve as an enablement platform, proven architecture, embedded processing, and real-time control ready to support your quantum application from the first experiment through to pre-production trials.

For organisations requiring deeper customisation or working outside NV sensing, Cosylab offers engineering as a service: co-development, architecture design, and full-stack integration support tailored to your roadmap and ways of working

Feature comparison:

How Engineering for Quantum Enables the Lab-to-Market Transition?

Quantum startups and research labs face a recurring tension: milestones demand working demonstrators, but resources are constrained. Building a custom control stack diverts engineering effort from the quantum innovation itself.

The GIRAFFE project started as a demonstration of what was possible and ended as proof of what is necessary. The journey confirmed that industrialisation in quantum is achievable, and engineering is the bridge.

Engineering as a service, from risk management and CE-marking to system verification, ensures that quantum products are built with the same discipline as medical or aerospace devices.

Finally Engineering for Quantum, either as a service or as an enablement platform such as starQ shortens development cycles, enables faster CE submission and more predictable demonstrator performance.

As one Cosylab engineer puts it:

“While the world debates the state of Schrödinger’s cat, we build the instruments to measure it.”

February 4, 2026 | From Lab to Fab: Quantum Sensing & NV Control Webinar

Join the "From Lab to Fab" webinar series on quantum sensing, and learn about exciting breakthroughs in quantum sensing applications using NV centers.

Read more

See how we tackled embedded quantum control with Silicon Austria Labs.

Read the GIRAFFE case study