A Modern Control System Rejuvenates Ocular Radiation Therapy

As the software and hardware components of the original control system had been in use for almost forty years, the need arose to finally upgrade the system and enable the PT facility to continue treating cancer patients efficiently and with at least the same throughput as of now.

Cosylab, as a specialist for accelerator control systems with many years of standing, won CCC’s tender for the modernisation of the control system of the eye treatment facility in Wirral, specifically the main controller (PDP11), central cabinet with roughly 1000 IO signals, PLC subsystem and cyclotron operator user interface.

A Great Way to Treat Eye Melanoma

The 60 MeV proton beam at CCC has a maximum range of 31mm in water. It is exceptionally suitable for treating any cancerous lesion within the eye, especially choroidal melanomas (malignant growth of the inside lining of the eye), choroidal haemangiomas (spread of rogue blood vessels), iris melanomas (melanomas in the coloured part of your eye) and conjunctival melanomas, which are tumours on the white of the eye and lid.

The existing planning system, EyePlan, includes the treatment planning system (TPS) and registration software and calculates the correction vector and patient gaze for therapy. All patients are equipped with markers (clips) before treatment sessions. Patients are planned with 2-D imaging (ultrasound and fundus photography), and the beam aperture is shaped to the treatment area using patient-specific collimators. In-room imaging is performed with X-rays while the patients are immobilised in a specialist chair. The chair is moved to the planned coordinates, allowing the eye to be located correctly in the fixed beamline. The correct eye position is verified with the in-room planar X-ray system before treatment delivery.

CCC’s Challenge

CCC is one of the UK’s leading cancer centres, and its facility, which specialises in eye tumour treatment, uses the proton therapy device (accelerator and beamline). The centre’s cyclotron was commissioned in 1984, and its single-room clinic has been successfully treating patients for ocular melanoma since 1989, with a throughput of currently up to 300 patients annually.

Because of its pioneering history, many of CCC’s accelerator beamline segments and quality assurance (QA) components were constructed in-house. With age and after several modifications to the cyclotron and transport line, the equipment and software were becoming progressively more challenging to maintain.

Hardware components of the control system were wearing out more and more from old age (such as capacitors drying out), spare parts for original hardware became hard to source, and new modern hardware was swapped in, bringing problems with making new interfaces to the old control system. The need to simplify the maintenance of the cyclotron hardware and system software by modernising subsystems became imperative.

The clinic’s management, therefore, decided to modernise its PT device and make its operation smoother while improving patient safety and enhancing the operators’ user experience (UX).

CCC’s PT eye clinic has significant throughput, treating patients up to 10 hours a day, and the doctors wanted to sustain this productivity throughout the refitting process. This had to be as non-disruptive as possible, with negligible downtime while preserving existing patient capacity.

"Cosylab gave us a tightly engineered solution for modernising our accelerator's control system and its user interface, giving us peace of mind regarding our patients' continued therapy for many more years."

Solution

Cosylab’s project focused on getting as much information about the existing control system as possible, creating a Gap analysis, defining the scope and reverse engineering certain parts of the machine’s current functionality that needed to remain intact (interfaces to bespoke hardware) while also developing new, modern features, to make the upgrade as efficient and functionally complete as possible. The latter fits well with Cosylab’s experience in engineering particle therapy control systems and integration solutions for eye treatment.

This included also overhauling the control system itself; we revamped it, not only in part. We replaced the main controller, the central IO-signalling cabinet, and the PLC subsystem, where we implemented updated solutions. Operators of the cyclotron would now have a contemporary user interface for a more efficient user experience.

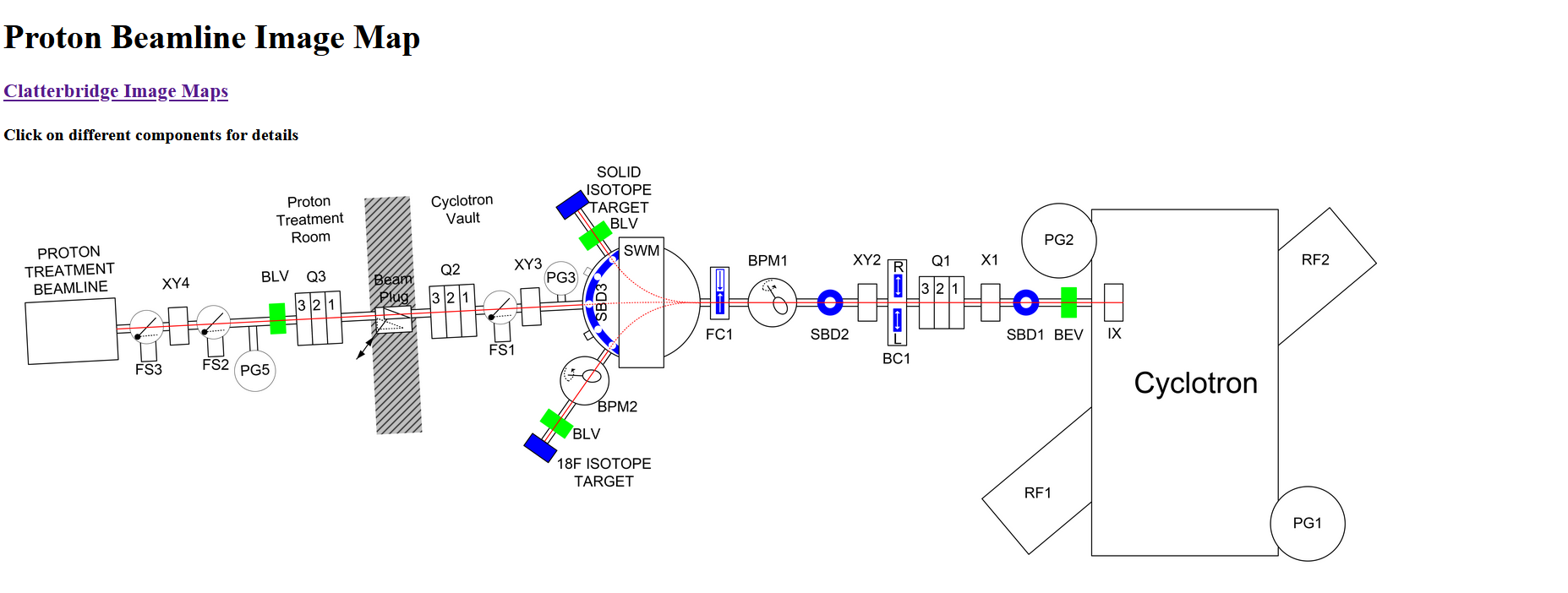

Figure 2: Topology of Clatterbridge

"Cosylab's people were outstandingly flexible and planned their approach carefully, rationally optimising the scope of upgrade work and chosen hardware replacements to stay within budget, assigned functionality and quality goals."

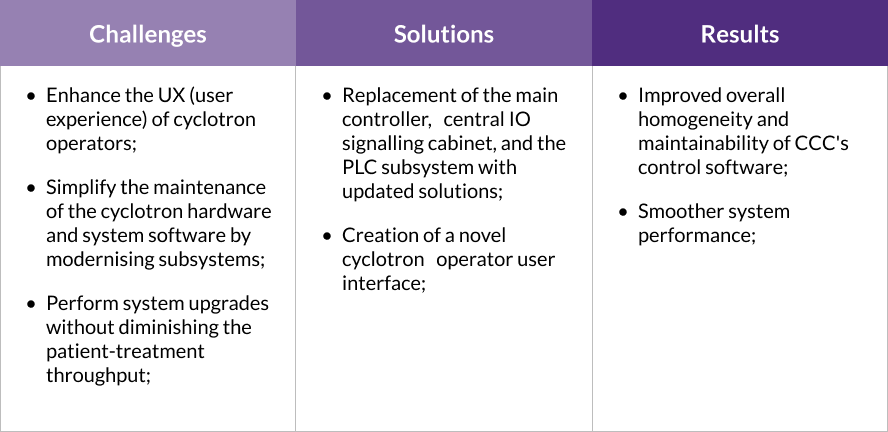

Objectives Clatterbridge achieved with Cosylab

Cosylab succeeded in improving the overall homogeneity and maintainability of CCC’s control software, specifically by upgrading the cyclotron control system (CS), and GUI for control system supervision.

Cosylab has painstakingly planned the switchover process and overhaul so that it would not impede CCC’s capability of ongoing patient processing and will introduce negligible downtime. The technicians will be able to retrieve data from the PT device much more efficiently and address drifts easily. The whole system’s performance will be smoother.

Cosylab is also integrating the third-party, legacy subsystems which were not replaced in the current modernisation of the control system. By creating a new user interface, we shall upgrade the UI to a unifying interface that will be more flexible and easy to use.

A Future-proofed Device

Cosylab is helping CCC achieve its primary goal, specifically prolonging the operational lifetime of the original accelerator hardware for years to come. Besides that, Cosylab’s upgrade solution will provide complete documentation that will enable CCC to demonstrate its PT device’s continuing compliance with the relevant medical regulatory standards. The device shall be as safe and effective as before the refurbishment, as original components will be replaced with upgraded ones without introducing additional risk.

Cosylab proved again that it can provide software functionalities and services not only for constructing new radiation therapy devices but also for prolonging the useful life of existing irradiation devices in challenged circumstances by thoughtful engineering and implementing upgrade solutions.

CCC’s case demonstrates the advantages of extending the duration of particle therapy devices’ effectiveness for curing ocular cancer, which can be applied in other clinics worldwide. Modernising the control system will also enable CCC to look towards additional enhancements to its PT device, such as speeding up operations by integrating a new dose monitoring system as well as a modern patient positioning system.

"We cooperated well with the Clatterbridge machine-control team that oversees the device's cyclotron. In fact, we soon developed a close rapport as we analysed the old control system and hardware subunits, planning our approach."

Image credits: The Clatterbridge Centre NHS Foundation Trust