Bringing a Revolutionary Quantum Microscope to Market in Only Six Months

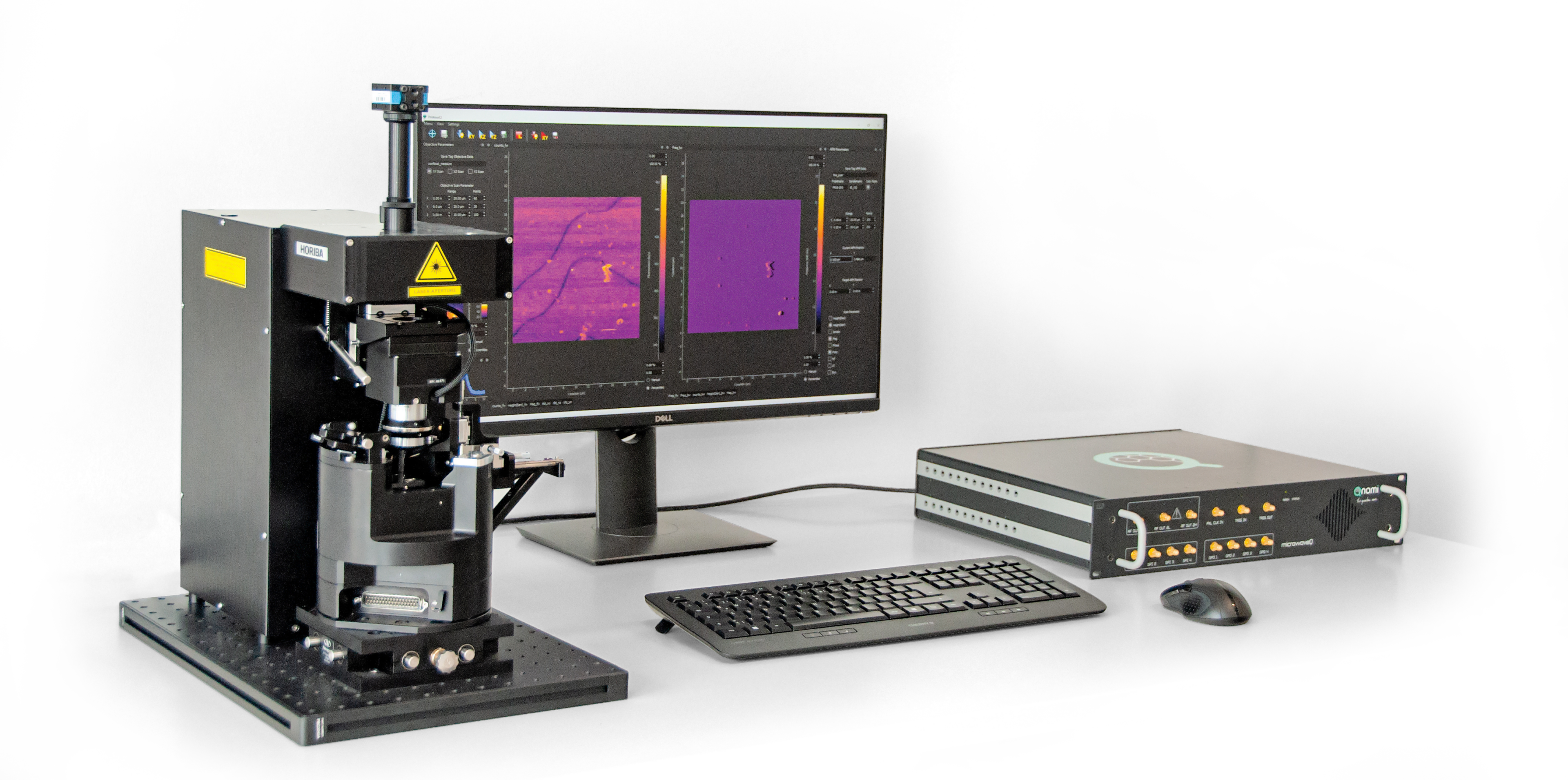

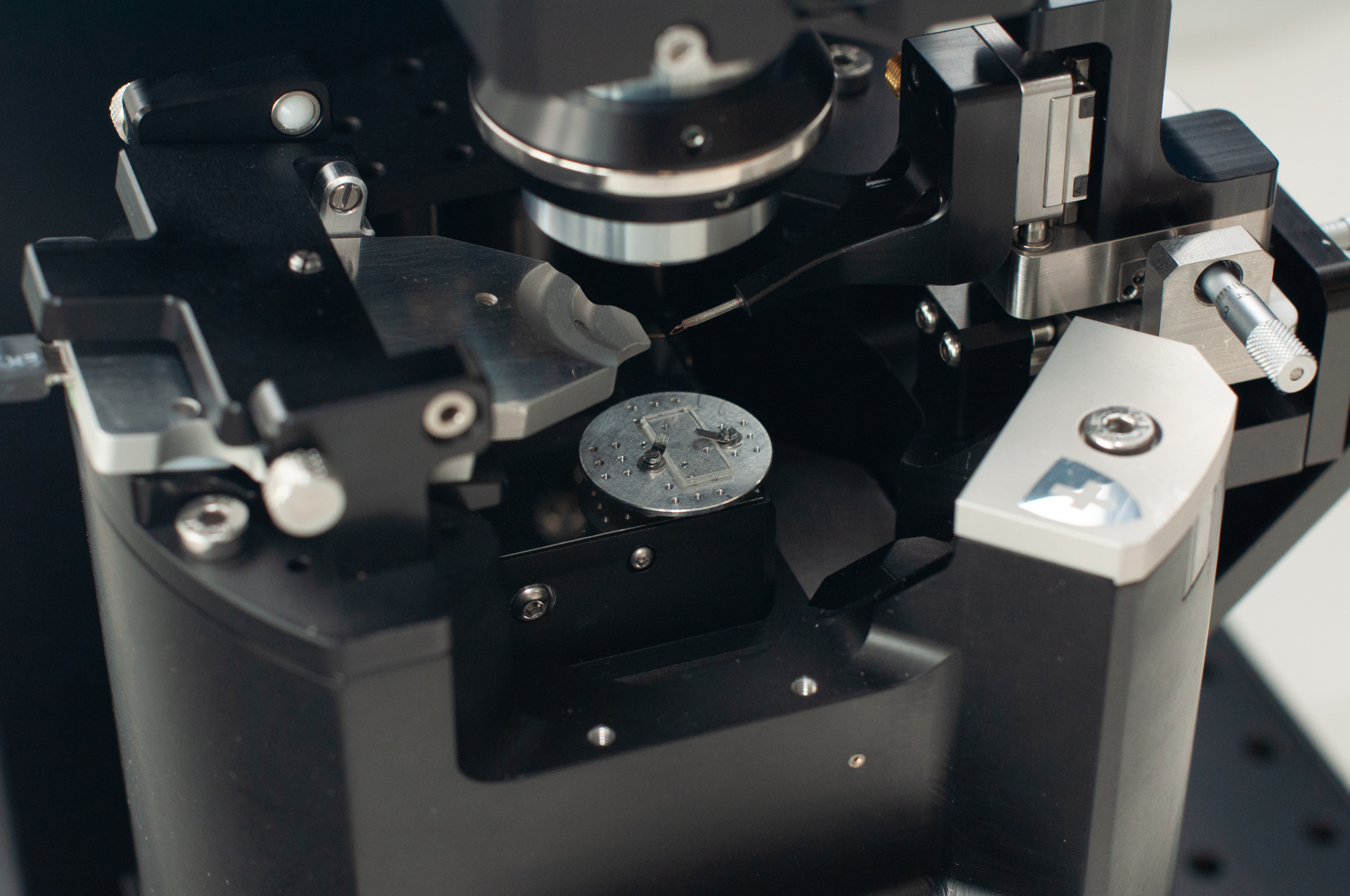

To get Qnami ProteusQ ready for market in record time, Cosylab supported Qnami in developing, manufacturing, and CE-marking MicrowaveQ, its quantum control hardware.

To succeed, Cosylab exploited its vast experience in delivering FPGA applications with giga-samples per second transmission rate and real-time control systems for advanced physics machines.

QNAMI AND THE FIRST QUANTUM MICROSCOPE

Qnami’s mission is to develop quantum sensing solutions for a broad range of applications from materials science and electronics to biomedical systems. Its goal is to support the development of technologies that improve people’s life. The company aims to support quantum applications in the following domains:

- High resolution imaging

- Quantum sensing

- Opto-mechanics

- Quantum computing

- Medical/Bio solutions

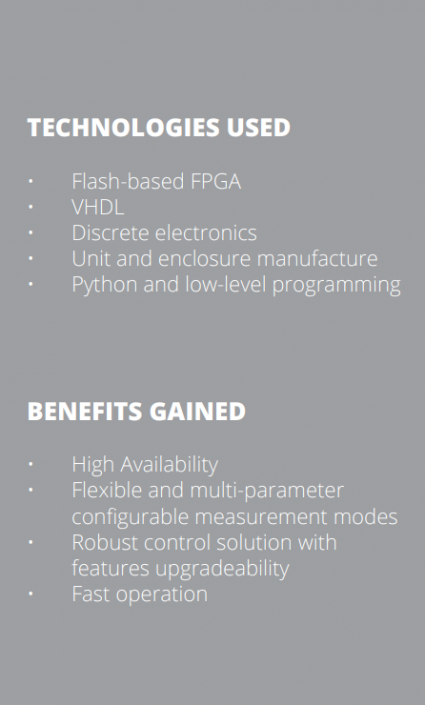

Qnami ProteusQ is the first complete Quantum Microscope that allows to measure magnetic fields never measurable before. At the core of the Qnami ProteusQ microscope is the Quantilever: an all-diamond probe engineered with one single nitrogen-vacancy centre at the apex of its tip. The Quantilever probe scans surfaces with extreme precision and allows non-perturbative analysis of a large variety of magnetic materials.

The microscope’s physics

The NV centre is a point defect in a diamond lattice, where two carbon atoms have been swapped for a nitrogen atom and a vacancy immediately alongside. By trapping one extra electron, the nitrogen-vacancy centre acquires spin properties making it an atomic-sized compass. The quantum state of the NV centre can be assessed by measuring its red fluorescence response to green laser excitation. The intensity of this response signal encodes quantum information related to the NV centre’s spin state. Local magnetic fields will alter this spin state. Thus, controlling such state enables the characterization of tiny magnetic fields which lay nanometres below the probe tip.

A detector in the Qnami ProteusQ optically captures the measurement data by counting single photons of the response signal at a very high rate. A quantum control hardware must serialise, process, convert and transfer the data to a computer that runs the high-level imaging and managing application for the Qnami ProteusQ.

“While working with Cosylab, we were looking forward to getting our system ready on time. The tight deadline did not prevent Cosylab to find optimal solutions and deliver the MicrowaveQ successfully. Qnami is now planning to ramp up the annual production of its Qnami ProteusQ units.”

THE QUANTUM CONTROL CHALLENGE

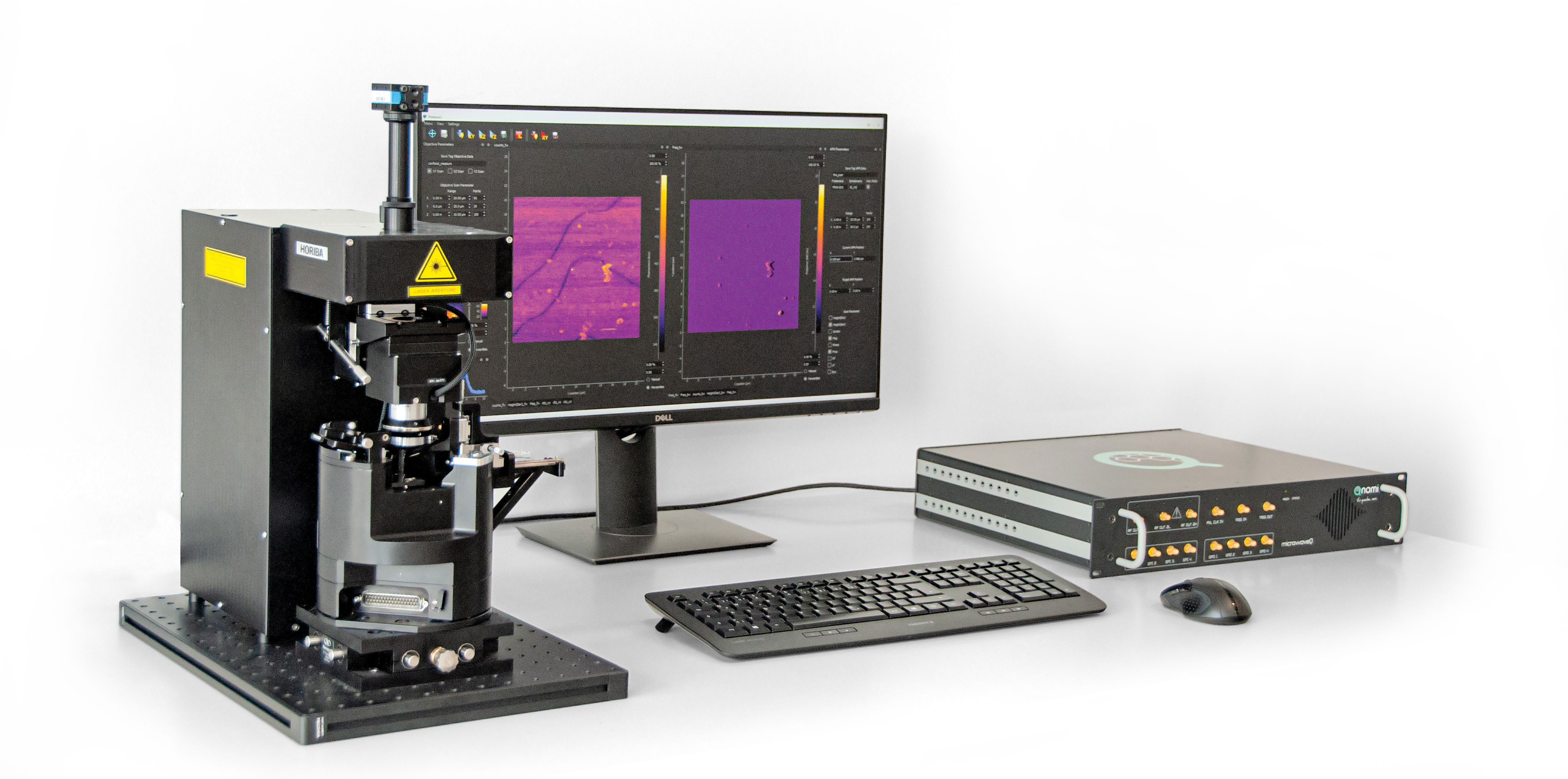

To achieve the photon read-out and transformation into measurement data, a high-speed industrial-quality electronics package was needed. The latter had to control a radio-frequency (RF) waveform generator, drive a laser, and perform single-photon counting and real-time data processing. In addition, it had to be designed to be smoothly upgradeable, reliable and optimised for serial industrial production.

The main challenge was to develop the quantum control of a single NV centre so that the full potential of the first scanning NV microscope could be achieved. Qnami ProteusQ was designed as a tabletop solution to measure magnetic fields with a magnetic spatial resolution previously achievable only at large accelerator facilities.

An additional challenge was the time-to-market requirement: Qnami ProteusQ had to be ready within only six months!

MicrowaveQ and Cosylab’s contribution to a cutting-edge Quantum Controller

Cosylab focused its efforts first on defining MicrowaveQ, the control system unit at the core of Qnami ProteusQ. MicrowaveQ controls the RF waveform generator, drives the laser, and performs the single-photon read-out from the NV centre, transforming it into measurement data by real-time processing.

Qnami and Cosylab agreed for a full-stack development effort: Cosylab would have to develop an all-in-a-box hardware with integrated firmware and software that meets the requirements and certifications for CE marking.

Cosylab decided to combine into MicrowaveQ a high-end RF Controller with an FPGA board. Cosylab based the SW interface for the computer-FPGA communication on an industry-standard solution, which provides state-of-the-art communication protocols.

“We asked Cosylab to develop and manufacture the quantum control system for Qnami ProteusQ in only 6 months. Cosylab worked at full speed and delivered the control system in time. We have chosen them to be the supplier of the MicrowaveQ in the future.”

Summary of the full-stack development challenge:

- Complex hardware (single-photon counting and RF generation);

- High-throughput data management (frequency and speed);

- Cutting-edge communication protocols (VHDL, Python-based HW abstraction and data acquisition systems);

- Development of MicrowaveQ HW, firmware, low-level API software;

- Full process for CE marking;

MicrowaveQ is flexible and supports different measurement protocols. The user sets these protocols by configuring multiple settings such as the number of RF frequencies, the frequency values themselves, the time durations, modes of counting and various other parameters.

Planning for future evolution is fundamental to enable fast development in an innovative startup that keeps the pace with the second quantum revolution. A fast-developing environment can cover the demands of continuously changing requirements.

Thus, the MicrowaveQ has some extra capacity to be versatile and able to keep up with future upgrades. The second quantum revolution may require, for example, more advanced measurement protocols or other measurement modes — perhaps arising from different market requirements.

“We consciously agreed to the tight half-year schedule and worked at full speed and in spite of the tight deadline we succeeded in delivering the first unit prototype in June 2019 to Qnami.”

WHAT MADE IT ALL WORK?

“It is in Cosylab’s DNA to go the extra mile and push the limits of how well we perform and what we can deliver on really short notice. Our talented engineering team rapidly produced a working prototype of the quantum control hardware and software based on a unique RF implementation.

In Qnami, we found a kindred spirit: a company that, like our own years ago, followed its dream. In their case, it was to bring quantum technology from the lab to market. Qnami decided to manufacture its quantum microscope in a way that is industry standard, is fully capable of withstanding daily life in a lab and can be upgraded down the road of the quantum revolution!”

Download the full Case Study on how to Bring a revolutionary quantum microscope to market in only six months.