ELBE Brings Its Timing System to the Future

With decades of experience in control systems for all accelerator types, Cosylab was a natural choice for HZDR to help with their upgrade of ELBE’s timing system to become easier to maintain as a homogenous solution and future-proof for flexibly conducting a significantly greater range of experiments.

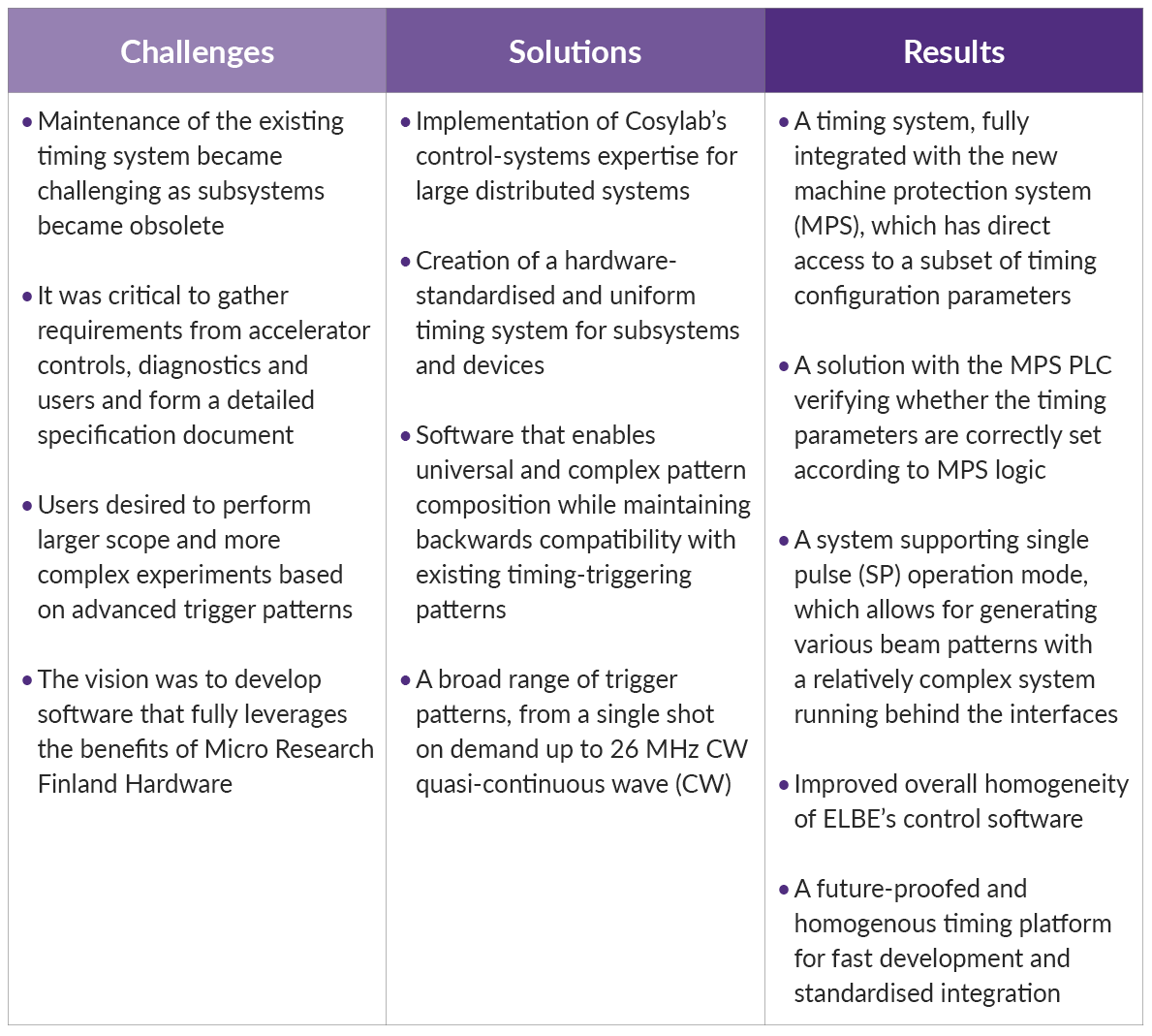

This case study describes the challenge of, and solution for, creating a universal and complex implementation of timing trigger-pattern composition and validity checks while guaranteeing backward compatibility with existing triggering patterns.

ELBE‘s Timing System Challenge

In the last two decades, ELBE’s engineers have been successfully modifying and extending the timing system to enable new experiments. Nevertheless, maintenance of the timing system had become an increasingly challenging exercise as components of subsystems were becoming obsolete.

“The most challenging part of the upgrade was gathering all requirements from accelerator controls, diagnostics and users and forming a detailed specification document. Before applying a single line of code or even touching one piece of hardware, we had intense meetings with our Cosylab partners to develop a shared vision of the new system and find the best solution for the ELBE accelerator.”

Michael Kuntzsch, HZDR Project Manager at ELBE for timing system update

A Homogenous Timing System for More Complex Trigger Patterns

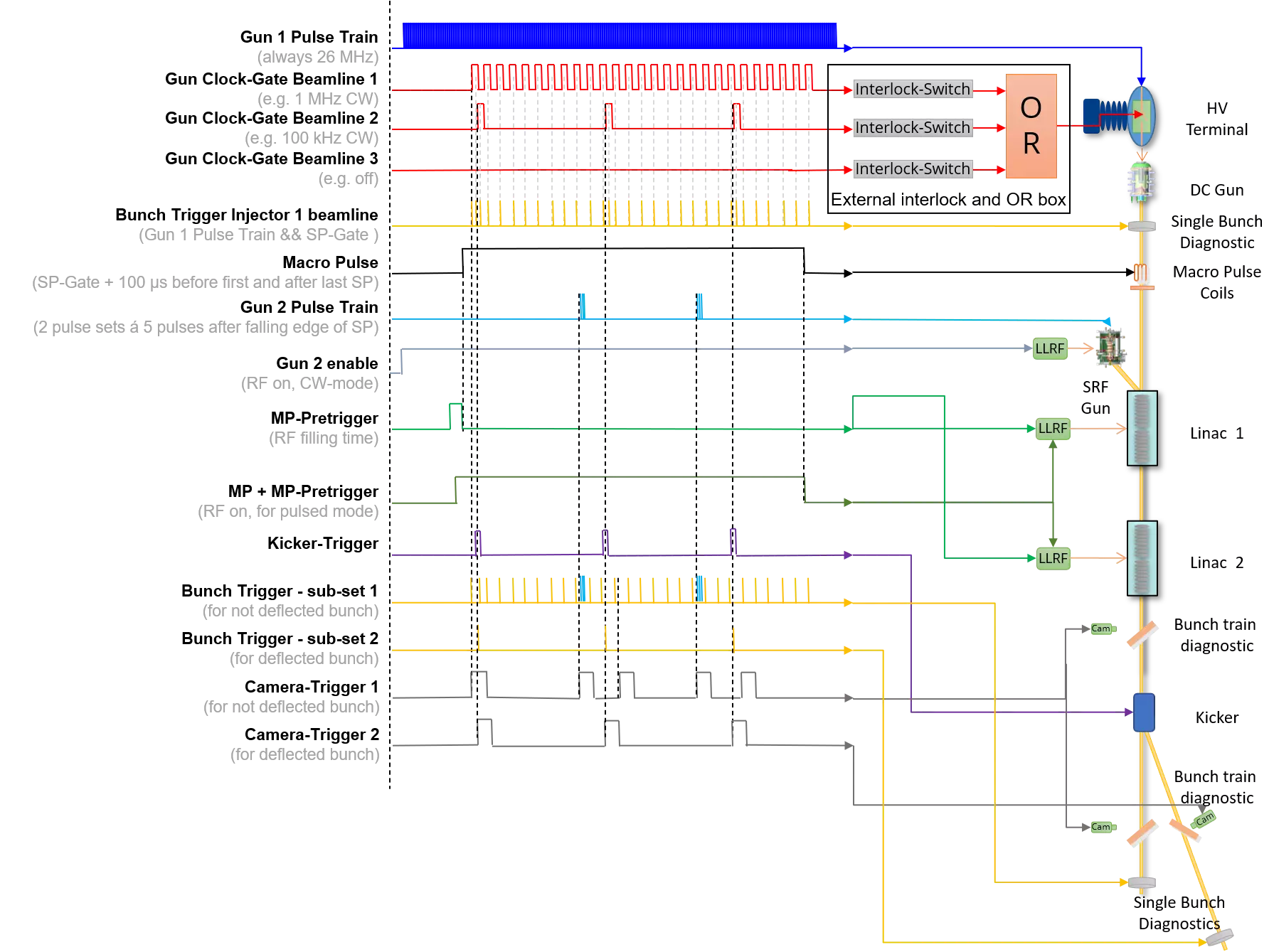

The demands on ELBE’s system were significant; for future experiments, it would have to be more uniform and better suited to generating new, more complex trigger patterns ranging from a single shot on demand up to 26 MHz quasi-continuous wave (CW). This requires a universal and complex implementation of the pattern composition and validity checks and must be compatible with all existing timing triggering patterns at ELBE.

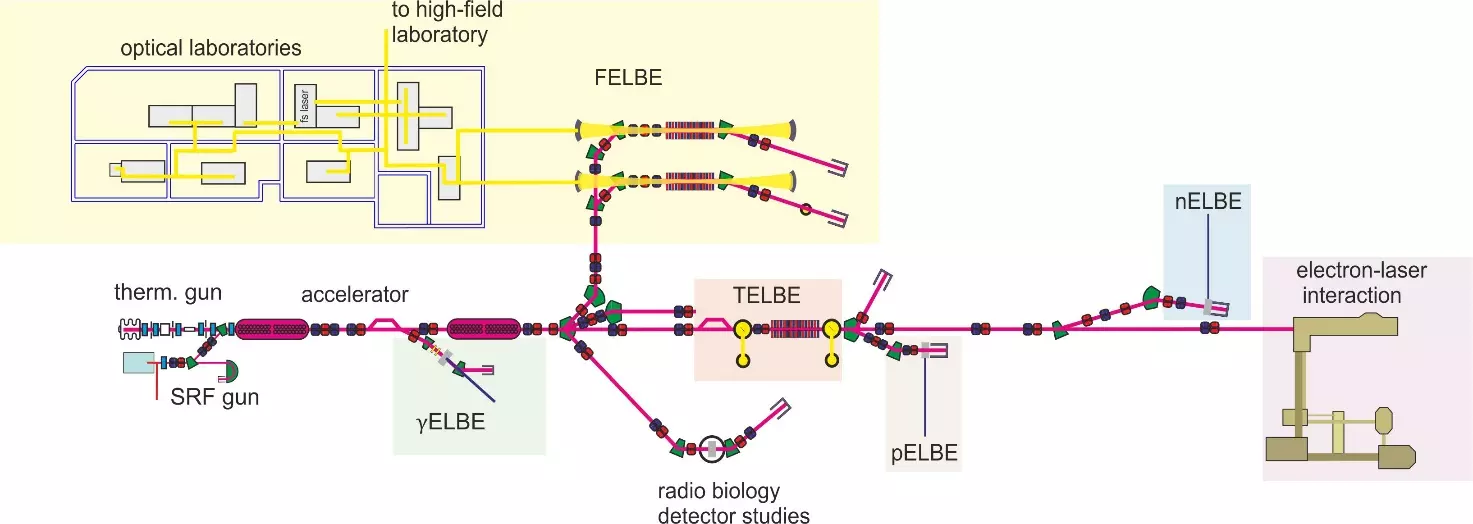

A Great Source of Secondary Radiation

ELBE’s electron linear accelerator (linac) drives electrons to energies up to 40 MeV with an average beam current of 1 mA in CW mode to generate secondary radiation, such as positrons, neutrons, intense THz and IR pulses and Bremsstrahlung.

Figure 1: Topology of ELBE beamlines

Cosylab Software powers Micro Research Finland Hardware for a modern and flexible timing solution

HZDR turned to Cosylab due to its extensive expertise in providing robust, standards-compliant, and easily-maintainable timing solutions over many years.

Cosylab understood HZDR’s need to make ELBE’s timing system more homogenous by using the Micro Research Finland (MRF) hardware platform and devised a modern and flexible solution based on the latter.

MRF hardware enables low jitter emission of timing patterns and a long-term delay compensation of the distribution network while allowing a modular approach to the timing system with a highly flexible topology.

Figure 2: Example of a timing structure at ELBE using two guns and a subsequent kicker to generate bunch pattern

On the one hand, event master modules (EVMs) are responsible for timing-event generation and distribution, while on the other, event receiver modules (EVRs) set the state of physical outputs based on received events. Each of the two ELBE injectors will have an event master module, generating an independent timing pattern, allowing for autonomous operation in separate beamlines and common emission into the ELBE accelerator.

“Together with Cosylab, we developed a detailed concept of the new timing system for ELBE. Based on this, Cosylab mapped the requirements to the MRF hardware and the Software and Firmware Framework to devise a solution perfectly tailored for ELBE without losing options for extensions or modifications. The software implementation hides the lion’s share of the complexity. It exposes only the core parameters, which allows the ELBE operators to focus on their tasks and minimises the interaction to set up appropriate timing parameters.”

Michael Kuntzsch, HZDR Project Manager at ELBE for timing system update

Form Factor: MicroTCA to the Forefront

We decided on using the MicroTCA form factor for the ELBE controller hardware wherever possible, but certain user/experiment stations at ELBE will use PCIe cards. The latter allows for up to 10 trigger outputs in a smaller package and is more cost-effective.

Beam diagnostics, low-level frequency control (LLRF) and other devices that need coordinated triggering will be connected to the event receiver modules in several ways. The latter will be through MicroTCA backplane trigger lines, front panel output (if TTL level is needed) or any of the Universal Modules that provide a variety of optical and electrical level triggers.

In the MicroTCA EVR, the number of external outputs is limited to 8 per module, four front panel TTL trigger signals and four signals from Universal Modules. Even so, Micro Research Finland extends the number of trigger signals via the rear transition module (RTM), where up to ten additional external trigger output signals can be configured and routed.

Figure 3: Micro Research Finland timing-receiver rear transition-module equipped with universal output-modules

Machine Protection and Timing Work as a Team

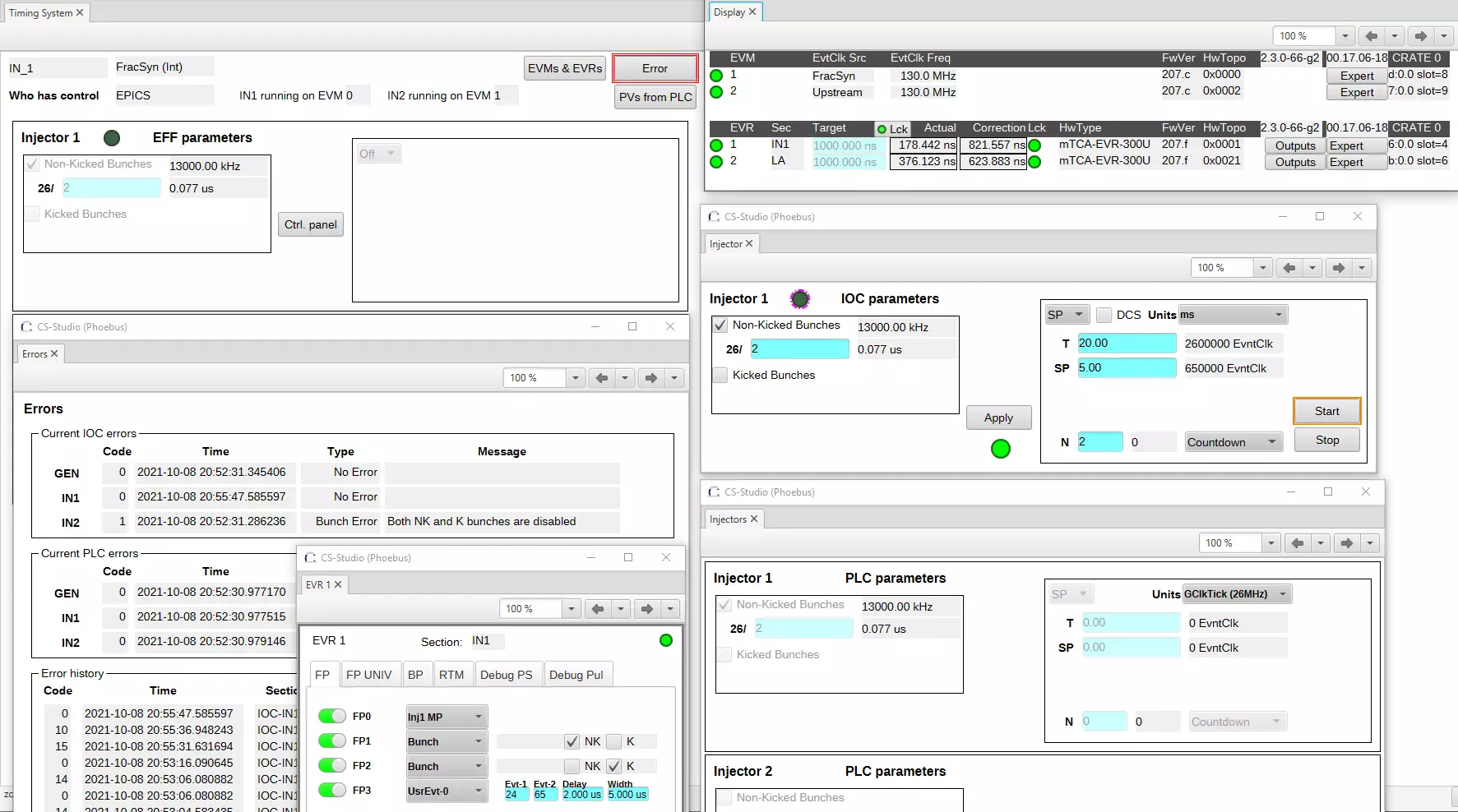

ELBE’s machine protection system (MPS) is the primary means of safeguarding the accelerator from loading potentially harmful configurations or even stopping the operation in case of faults. The MPS PLC is connected to the timing system computers and other PLCs (programmable logic controllers) running in the system and has direct access to a subset of timing configuration parameters.

The timing system receives via the PLC data that defines the operational mode, such as RF configuration or injector selection. Additionally, the MPS PLC verifies whether the timing parameters are correctly set according to MPS logic.

One outstanding feature of ELBA‘s new timing system is the single pulse (SP) operation mode. The latter allows for generating various beam patterns with a relatively complex system running behind the interfaces. The period of the SP pattern can be set as low as 115 ns on one side and up to 9 hours on the other. The lowest value for the duration of a single pulse is limited to 38.5 ns or one bunch from a 26 MHz gun. This allows for high resolution and exact control of the SP beam, but it pushes both the hardware and software capabilities of the new timing system to the limits.

“The path from specification to the last line of code was paved with numerous stepping stones. The vast spectrum of expertise inherent to the Cosylab team was a key to coming to the well-thought-out solution we have at our machine now. Working with the Cosylab team was an enriching experience, and I would not hesitate to repeat it.”

Michael Kuntzsch, HZDR Project Manager at ELBE for timing system update

Objectives ELBE achieved with Cosylab

Cosylab delivered the MRF-based upgrade of ELBE’s timing system in the spring of 2023, in close cooperation with the HZDR engineering team, and the transition from the legacy timing system to the new timing generation and distribution is still in progress by the team of ELBE controls group and planned to be completed by the end of the year. The latter will enable the facility to conduct novel types of experiments and make it one of the world’s most versatile accelerator-driven photon and particle sources.

Figure 4: Timing system expert GUI

The HZDR’s centre for high-power radiation sources now has a flexible timing system that enables parallel operation of electron sources and future kickers to simultaneously serve multiple end stations, increasing the experimental throughput.